Fracturing fluid and fracturing additives

Clean fracturing fluid

1. Introduction

The clean fracturing fluid produced by the company is also designed and developed by the company; with a complete formulation and production and testing equipment. The conventional system is properly adjusted in the process of polymerization in terms of different temperatures, geological conditions and fracturing technologies in order to meet the customer requirements.

2. Technical Characteristics

(1)The clean fracturing fluid system is an anionic surfactant. As sulfonic acid group is introduced, its resistance to temperature and salt is increased. In addition, the anionic surfactant is of the same properties as the formation, so it is not absorbed by formation, hence reducing the damage to formation in immediate vicinity of wellbore;

(2)The clean fracturing fluid system has fast dissolution rate and dissolves uniformly, with its viscosifying time at 10min, so it is suitable for field preparation and use.

(3)This clean fracturing fluid system is not much affected by biodegradation factors, so it is suitable for long-time storage; as a natural organic polymer, guar gum is easily biodegradable.

(4)Its resistance to shear and temperature and its rheology are better than similar products; (See Qualification Documents for the testing reports by Research Institute of Petroleum Exploration & Development (RIPED) Langfang Branch and SINOPEC Research Institute of Petroleum Engineering).

(5)It has extensive sources of raw materials, which would not be affected by international market, with stable cost price.

(6)Low residue level (≤ 70mg/L; guar gum ≥ 200mg/L);

(7)Small formation damage rate (≤20%; for guar gum, 10%~50%)

(8)Characteristics of gel breaking

1.Gel breaking at low temperature of <20°C;

2.The gel breaking liquid is not used for VES, which is not degraded when mixed with hydrocarbons.

3.The gel breaking liquid is surface-active, easily for flow back.

4.The hydration viscosity of gel breaking liquid is less than 1.4mPa•s.

(9)There is no data for low friction (the interfacial tension of water is 50~70 and that of clean fracturing fluid is 210)

3.Technical Index

No. |

Evaluation item |

Clean fracturing fluid |

Modified |

Standard |

||

1 |

Resistance to temperature and shear (130°C, 170s-1, 120min), mPa·s |

>93 |

≥50 |

≥50 |

||

2 |

Residue level, mg/L |

≤70 |

>200 |

≤100 |

||

3 |

Visco-elasticity |

Storage modulus, Pa |

≥1.8 |

≥1.5 |

≥1.5 |

|

Loss modulus, Pa |

≥0.3 |

≥0.3 |

≥0.3 |

|||

4 |

Static filtration |

Coefficient, m/ |

≤6.17×10-4 |

1~3×10-4 |

≤1.0×10-3 |

|

Initial filtration, m3/m2 |

≤6.42×10-3 |

≤5.0×10-2 |

≤5.0×10-2 |

|||

Filtration rate, m/min |

≤2.73×10-5 |

4~5×10-5 |

≤1.5×10-3 |

|||

5 |

Formation damage rate |

20% or so |

10%~50% |

≤30% |

||

6 |

Gel breaking performance |

Gel breaking time, min |

Adjustable according |

60 |

≤720 |

|

Apparent viscosity of |

≤1.4 |

3.4 |

≤5 |

|||

Surface tension |

≤24.5 |

25.2 |

≤25.0 |

|||

Interfacial tension of gel |

≤1.49 |

—— |

≤2.0 |

|||

Remark |

References for modified guar gum performance parameters [1] Performance study of cross -linked guar gum fracturing fluid Performance evaluation and field tests of new clean fracturing |

|||||

4.Production Capacity of Additive Fluid

Shandong Nalong Hi-tech Petroleum Technology Co., Ltd. is a subordinate to Shengli Highland Petroleum Engineering Services Co., Ltd.. It has registered capital of 10 million yuan, and the current total asset of 200 million yuan, occupying a plant area of 9,800 m2. To satisfy the demands from oilfields, the company has developed 19 types of new and high-efficiency oil production additives, including oligomeric fracturing fluid system, acid thickening agent system and amphiphilic polymer fracturing fluid system, which contributes to outstanding stimulation performance for the users. It gains prevailing popularity among a number of large fields of the country.

The company’s macroeconomic objective is to build an innovative Nalong and a century Nalong brand. It has an annual additive liquid supply capacity of one million m3 for different blocks in different oilfields; its production personnel and technical personnel all hold valid certificates. The company fulfills every customer’s order while assuring the quality and quantity.

5.Appearance Handling and Packaging

Whether the products are shipped to domestic customers or foreign customers, the company will develop the appropriate packaging mode according to the different needs of customers. Single packing bag uses three-in-one thick bag. The lined bag is plastic, composed of three layers to ensure it is tight with no moisture absorption and leakage. The whole tray uses whole-body plastic package, making sure there is no loose, damage and loss during transport. The product packaging meets the requirements of long-distance transport and handling, with the weight of 1 ton for each package. In addition, the company can provide package according to the customer's specific packaging requirements.

Field Application

1.Oil field application of low temperature series products (20°C~80°C)

The low-temperature series products are mainly used for fracturing in low temperature formations in Xinjiang and sand control technology in low temperature wells of other oilfields. They have fast, controlled and complete gel breaking characteristics at low temperature. The following are application examples of low temperature series products.

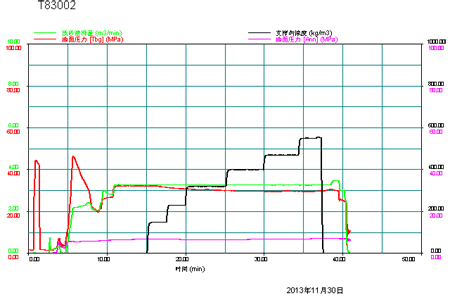

Operation curve graph for Well T83002 in Block 8, No.2 Oil Production Plant, Karamay, Xinjiang Oilfield, PetroChina

According to the analysis of curves and fractures created in the previous three times of fracturing, the clean fracturing fluid has little filtration, with strong capacity of fracture generation. The maximum sand ratio is 55%, with very small pressure fluctuations. The clean fracturing fluid has good sand-carrying capacity and good resistance to temperature and shear. After fracturing, the oil production is increased by 4.7 t/d.

2.Oil field application of middle temperature series products (80 ЎгC~120 ЎгC)

The middle temperature series products are widely applied and technologically promoted in the major oilfields in China. There were field applications in nearly 150 wells in Shengli Oilfield, Zhejiang Oilfield and Xinjiang Oilfield, etc. respectively. Technical exchanges and laboratory evaluations were carried out in the Southwest Petroleum Administration and Changqing Oilfields, etc.. The good stimulation effect has been obtained in the applied wells for the Client. The application examples are as follows.

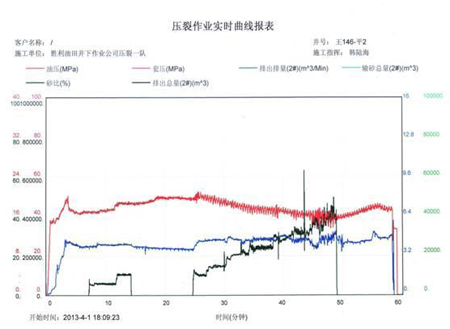

Field applications in Well Wang-146 - Ping 2 (horizontal well fracturing; reservoir temperature: 85 ЎгC)

The lithology of Cx3 sand formation in sand Member 4 of Wang-146 block is mainly taupe oil immersed siltstone, with developed gray argillaceous siltstone and limy siltstone. The maximum flow rate is 4.5m3/min, burst pressure 50MPa, fracturing pressure 60-40MPa, maximum sand ratio 62%, pumped fracturing fluid 261.8m3 and25m3 of sand. After fracturing, the daily oil production was increased by 9.6 t.

3.Oil field application of high temperature series products (120 ЎгC ~ 150 ЎгC)*

As company’s main product, the high temperature series products are mainly used in the deep and tight lithology reservoirs in major oilfields in China, with good resistance to temperature and shear, little filtration and controlled gel breaking time. Currently, the high temperature series products have been applied in more than 60 wells in Shengli Oilfield, with success rate of 100% and good stimulation results.

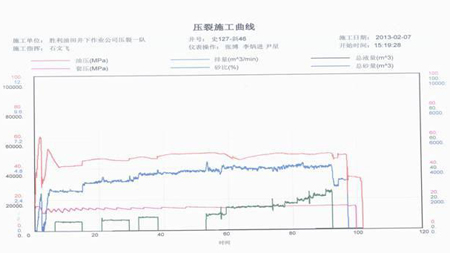

Field applications in Well Shi-127-x46 (conventional fracturing; reservoir temperature: about 130 ЎгC)

Two layers were fractured for this time, with 23.0m (vertical thickness of 22.0m) of dipped interpreted reservoir thickness and 26.5m of fracturing layer span. The logging data shows that the sand body of layer to be fractured is thick; No. 22 layer is pure, and its deep induction resistance value is relatively high, its oil potential is good and reservoir pressure is high. It is predicted that the layer has flowing production period. No. 21 layer is slightly poor, showing impure sand body, and relatively low deep induction resistance. After fracturing, the daily oil production was increased by 6.6 tons.